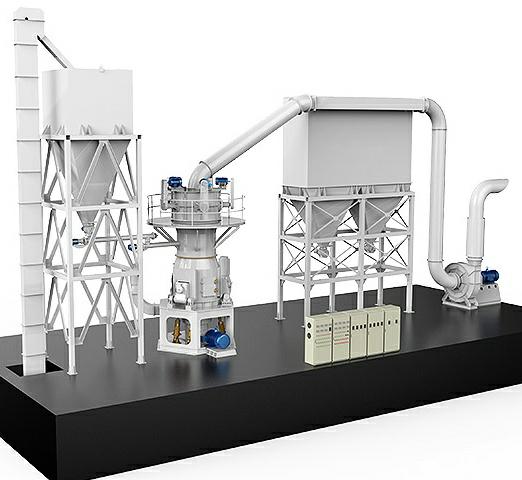

Superfine Kaolin Powder Milling Production Line

Lead: Kaolin is widely used in coatings, paper making, ceramics, refractory materials, military industry and other new materials industry. In the past, the only crude ore selling and simple processing of kaolin is seriously wasted the mineral resources. For further explore the value of kaolin, SANDMINE combined the kaolin usage characteristics by customers has developed new-type superfine kaolin powder milling machine and designed a complete set of processing techniques and solutions. The size of the milling powder can reach 325-2500 mesh at once during processing, greatly increased the added value of kaolin.

With the development of science and technology, the application range of kaolin is also expanding. It is widely used in field from construction, ceramics and refractory materials to paper making, petroleum, chemical, rubber, plastics, coatings and other dozens of industries. In order to produce the high quality kaolin powder to meet the market requirement, we need to speed up the technology upgrading of powder milling equipment.

SANDMINE adopts Germany advanced technology combining the kaolin nature character to produce the new type kaolin powder milling machine, which combines the capacity of crushing, impacting and milling together. This series equipment has the advantages of high output capacity, output material reasonable gradation and superfine output size. The final size can reach 2500 mesh at most. It is the best choice for kaolin powder milling.

Processing diagram of superfine kaolin powder milling

Maximum Feeding size:≤10mm

Final output size:325-2500 mesh

Output capacity:1-25t/h

Application: it is widely used in the field of electricity, metallurgy, cement, chemicals, building materials, coatings, paper making, rubber, medicine and food.

Raw material: all kinds of non-metallic mineral with Mohs hardness below 7 and moisture content less than 6%, like talc, calcite, calcium carbonate, dolomite, potassium feldspar, bentonite, kaolin, graphite, carbon, fluorite, brucite and etc.

Advantages

Strong systematicness: SANDMINE offers the complete overall process design.

Easy to maintain: the grinding rollers can continuously work for 30 days with once grease injecting. The ordinary milling machine need grease injecting every 24 hours.

It adopts squirrel cage cone turbine classifier. The powder size is variable between 80-600 mesh.

It adopts the high-pressure centrifugal fan with great air volume and air pressure.

SANDMINE will choose different type of machine for different customer needs on output size and output capacity based on the difference of the raw material. SANDMINE can customize the most suitable production line and working site for customers. If need and help, please give us the call 021-5820 6908.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia