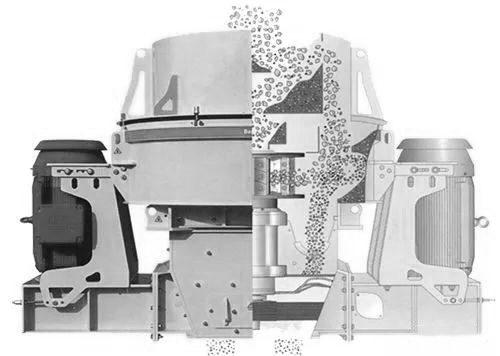

Why material congestion is so common in sand making machine?

Material congestion happens usually in sand making machine, when material congestion happens, the manufacturing schedule will be slow, then cause economic interest damage to the company. To solve the problem, knowing the reason of material congestion is very important.The following 8 reasons can help to solve the material congestion.

1. The water content of the material is big.

If there is too much water in the material, it will stick on the sand making machine, the solve method is to heat the material on the feed opening.

2. The material is too hard or the size is too big.

When the material is too hard or the material size is too big, the material will block in the machine, so the material should be in suitable size and hardness.

3. The feeding speed is too rapidly.

The feeding speed can’t match the crushing speed, the feeding is fast, but the crushing is slow, the machine works under overload, then cause material congestion.To solve the problem, the material feeding should be even and continuous.

4.The tightness of the V-belt is not suitable.

When sand machine works, the V-belt will deliver the power to the pulley, when the V-belts loosen, it will rotate with the pulley, not to make the pulley rotating. The material can’t receive the normal crushing power, then will be blocked in the crushing chamber.

5. The discharge opening size is not suitable.

When crusher works, if the materials discharge too slowly, the following crushed material will be piled in the discharge opening and the crushing chamber then hinder the material discharge.

6. The accessory equipment can’t match well

For example, if the capacity of belt conveyor is bigger than crushing capacity, the material can’t be crushed timely then the congestion will happen.

7. Operation fault

Operation fault is a common reason of material congestion.The operator must be trained professionally before operating the machine.

8.The sand making machine problem

If choose a wrong sand making machine model, the material congestion will also happen.

When choose the model, please tell the technician about the material features to choose the suitable model.

And please choose the qualified crusher manufacturer to ensure the crusher performance.

If you have the problem of material congestion, please check the machine from the above reasons, solve the problem to improve manufacturing efficiency.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia