The role of impact crusher in sand aggregate production line

Impact crusher is a kind of equipment which uses impact energy to crush stone, because it is a vertical shaft design, also known as vertical shaft impact crusher, vertical sand machine.

Vertical shafts impact breaking technology originates from foreign countries, to be exact, is the sand grinding technology of American Bamak Company. Through the introduction of technology in the 1980s and 1990s, it has settled down and developed continuously in China. However, the vigorous development and breakthrough development of vertical impact crusher is still after 2000, because with the acceleration of urbanization in China, natural gravel and sand can no longer meet the building needs, mechanism gravel and sand gradually rise, and sand equipment has ushered in a development period, including vertical impact crusher.

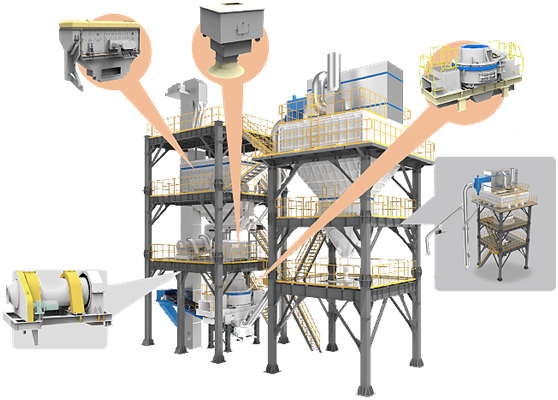

After years of development, impact crusher has been developed for many generations and become a common crushing equipment for sand and stone crushing. Till now, SANDMINE impact crusher has two types: vertical shaft impact crusher and building type. Although the impact angle, wear-resistant material and impeller shape of impact crusher are constantly optimized, the working principle is unchanged.

There are two working principles of impact crusher, one is full-center feeding, the other is combination of waterfall center feeding.

Full-center feeding: After the pebbles or fine pebbles that reach the feeding specifications (generally below 40 mm) enter the impact and break, the initial acceleration is centrifuged by the dividing cone. The material moves to the edge of the impeller and is thrown by the throwing head. The thrown material has a high speed, and then impacts the circumferential guard plate and is rebounded by the circumferential guard plate, and counteracts the material thrown out in the next wave. Of course, after a long period of production, a cushion layer will be formed on the perimeter guard plate, and the role of materials will increase.

Waterfall feeding: After the stone or fine gravel which reaches the feeding specifications (generally below 40 mm) enters the impact breakage, one part of the material enters from the center of the impeller, and the other part enters from the periphery of the impeller. The material entering the center will be initially accelerated by the dividing cone, and run to the edge of the impeller to be accelerated by the throwing head. The accelerated material will impact the material curtain, and some materials will impact the perimeter plate and rebound and break up when they have kinetic energy.

Two different working principles, material entry mode through the upper end of the impeller powder device to achieve. Two different working principles have also achieved the impact crusher's two major roles in the sand aggregate production line: fine grinding sand making and aggregate shaping.

With the vigorous development of high-quality sand aggregate production line and the continuous implementation of professional customization project of environmental protection and quality, impact crusher will be more used in sand aggregate production.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia