Six key points of jaw crusher daily operation

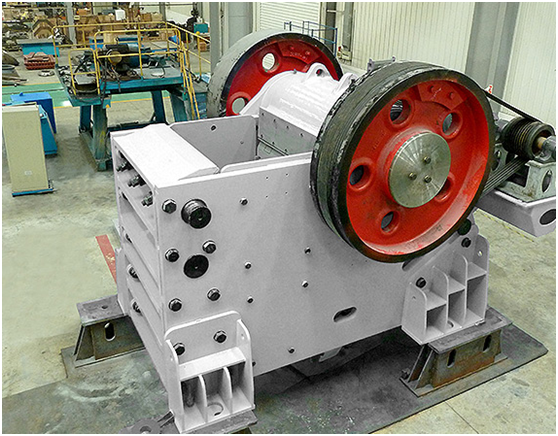

Jaw crusher has the advantages of simple structure, large crushing ratio, was widely used in various industries, let’s see the six key points of jaw crusher daily operation.

01.Test with no load

1.Make sure that the connecting bolts are tightened before the test, and confirm the lubrication on every parts.

2.After 2 hours continuous operation, bearing temperature rise does not exceed 30 ℃.

3.After 8 hours continuous operation, bearing temperature rise does not exceed 35 ℃.

4.Flywheel, pulley wheel runs smoothly, all parts without friction, chip drop, no abnormal noise.

5.There is no obvious movement when adjusting the frame between wedge and the behind frame.

02.Pre work before starting

1.Check the lubrication of the bearing carefully and whether there is sufficient lubricating oil at the joint place of the toggle plate.

2.Carefully check that all fasteners are fully tightened.

3.Check whether the belt is installed correctly and in good condition, replace in time if any worn. When there is oil on the belt or pulley, wipe it off.

4.Check whether the protective device is good or not, , eliminate in time when finding unsafe phenomenon.

5.Check whether there is ore or debris in crushing chamber, if yes,it must be cleaned to ensure no-load start.

03.Start requirement

1.After inspection, make sure that all parts are in normal condition before starting.

2.Start under no-load condition

3.Give advance notice with a bell or signal before start.

4.After start, if an abnormal phenomenon is found, the operation should be stopped immediately, and the crusher shall be restarted only after the abnormal conditions are identified and solved.

04.Operation instruction

1.Feeding material after crusher works in normal condition.

2.The material should be evenly feeded to the crusher chamber to avoid lateral loading or overloading.

3.Under normal working, the temperature rise of the bearing shall not exceed 30 ℃ and the highest shall not exceed 70 ℃. When exceed the above-mentioned temperature, stop the machine immediately, find out the cause and eliminate it.

4.Before shutdown, stop feeding and shut down the motor only after the material is completely discharged from the crushing chamber.

5.Close the motor immediately when material blocks in the crushing chamber, and start again after discharging the material.

6.After the crusher worked for a period of time, all fixed parts should be re-locked.

7.The place under toggle plate needs regular cleaning, to keep non-inclusion between toggle plate and movable jaw.

8.Change another side to use when worn on the jaw plates.

05.Lubrication

1.Timely lubrication on friction surface to ensure normal operation of the machine and prolong the service life of the equipment.

2.General lithium-based grease or a compound calcium-based grease are used as lubrication grease, or the grease required by the manufacturer.

3.Every time add 50% volume to the bearing seat,and every nine shifts shall be filled once every 3-6 months. The way of the ball bearing shall be cleaned with clean gasoline or kerosene when the oil is changed.

4.Add some grease between toggle plate and toggle plate seat.

06.Security control

1.The operator must be educated in safety technology before operating the machine.

2.Peep the machine from the above is forbiddened during machine working.

3.Adjust, clean or repair are forbidden during machine working.

4.Move the ore on the feeding place or from the crushing chamber are forbiddened during machine working.

5.Electrical equipment shall be grounded, wires shall be insulated, and shall be installed in hoses.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia