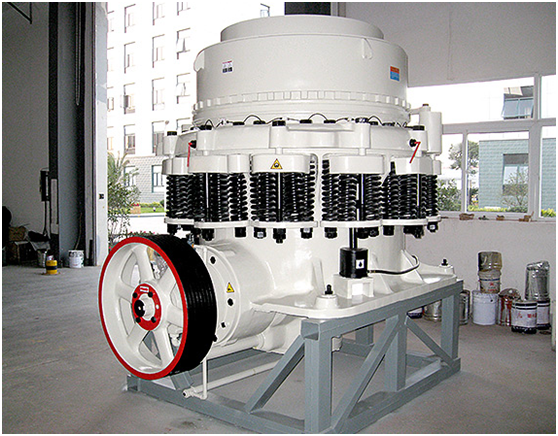

Here are four common dust-proof ways of cone crusher

The working environment of crushing equipment is bad, and a lot of dust will be produced in the process of crushing materials. The poor dust prevention will affect the working efficiency of crusher, destroy the lubrication system and reduce the service life of equipment. So it is very important to do a good job of dust prevention. Now let's look at four common dust-proof methods of cone crusher.

Four Dust-proof Methods

1.Water-sealed dust-proof device

This kind of dust-proof method depends on the annular water supply tank on the bowl bearing rack and the spherical ring fixed at the lower end of the conical drive body. The spherical ring is inserted into the annular water supply tank. When the crusher works, the spherical ring blocks the dust and causes it to fall into the water. The water seal is flowed into the water supply tank from the intake pipe. When the water supply tank is filled, it overflows to the external annular drainage tank, so that the backwater with dust flows out of the machine through the drainage pipe.

2.Apron Pair-water-sealed Dust-proof Device

A rubber ring pair is made according to the inner side of the cone crusher drive and the outer side of the bowl bearing rack. The taper rubber ring is installed on the bowl bearing rack, and the cylinder rubber ring is installed on the cone crusher drive, ensuring that the rubber ring pair contacts closely in any direction.

When the crusher works, the cylindrical rubber ring rotates and oscillates with the crusher, while the tapered rubber ring on the bowl bearing frame is always close to the cylindrical rubber ring under the action of elastic force. Thus, the dust can be avoided. However, due to errors in fabrication and installation, a very small part of the dust enters the flume. Therefore, it is necessary to use water seal to prevent dust.

This kind of dust-proof is essentially two ways of dust-proof. Apron material must have good elasticity, wear resistance and heat resistance. At present, this kind of rubber sheet is very few. Using ordinary rubber plate or V belt, the service life is very short.

3.Dust-proof device for water-sealed felt

Industrial felt with thickness of 3-8 mm is selected. The felt is fixed on the outer edge of the oil return groove of the bowl-shaped bearing rack of the cone crusher with a pressure plate. The height of felt should be ensured to have a compression of 3-5 mm. Lubricating oil should be poured on the felts to reduce the wear and tear of the felts.

This is also a two-way dust-proof device. In the water-sealed dust-proof device, most of the coarse dust has fallen into the water, and some fine dust fly into the water, which is blocked by felt, thus preventing the dust from entering the lubrication system.

This method is simple, has good sealing effect and long service life. Practice has proved that after several months of use, the bowl bearing is very clean, no fine sand and dust, no change in lubricating oil quality and no damage to felt.

Foam dust-proof device

A concentrator in Jilin handles 1 500 tons of ore per day. The ball bearing parts of two crushers in its crushing system are equipped with rubber dust-proof rings, and the bearing seats are welded with dust-proof intake pipes and drainage pipes. A water-sealed dust-proof device is installed to prevent dust from entering the ball bearing and causing wear and tear.

1.Problems Existing in Dust-proof Methods

The original dust-proof structure is shown in the following figure. Through several years of use, the following shortcomings of this dust-proof method are found:

Because the moving cone rotates 18-20 times/min with the rotation of the eccentric sleeve, and sometimes the synchronous speed with the eccentric sleeve is as high as 300 r/min, the rubber dust-proof ring wears quickly. When the gap between the moving cone dust-proof baffle and the rubber dust-proof ring is more than 1.5-3.0 mm, a large number of dust-driven cone enters the water packaging along the dust-proof baffle, clogging the water sealing tank and drain pipe, and depositing dust. In the water-sealed tank.

When the pressure in the water pipes is high, water flows into the oil tank through the oil retaining ring from the return pipeline of spherical bearings. Therefore, it is necessary to remove and check the water encapsulation device frequently and replace the lubricating oil in the oil tank, which not only increases the labor intensity of workers, but also causes a lot of waste.

2.Improvement of Dust-proof Methods

Firstly, the water-sealed inlet pipe 10 and drain pipe 1 are dismantled, and then the annular water-sealed groove on the spherical bearing seat 2 is tightly sealed with calcium-sodium base grease. Depending on the spherical dust-proof baffle 8 at the lower part of the crushed cone and the calcium-sodium base grease in the annular groove of the spherical bearing seat, the dust is blocked or adhered to the calcium-sodium base grease through the rotation of the body, thus the dust is blocked on the spherical bearing. Outside the block.

3.Usage effect

The application proves that the effect is better.

Water saving. Two cone crushers can save 116.6 tons of clean water per day, 31482 tons of clean water per year and cost nearly 100,000 yuan.

Increase the amount of treated ore. It solved the problem that dust often blocked the water sealing tank and drainage pipe, reduced the maintenance times and prolonged the start-up time. Two cone crushers treated 490 tons more ore per month, 4410 tons more ore per year, with an annual benefit of more than 20,000 yuan.

Save lubricating oil. After changing the dust-proof mode, the phenomenon of oil change caused by water intake in the lubricating oil station has been solved, which can save 1620 kg of lubricating oil per year and more than 10,000 yuan in cost.

Save electricity. Due to the removal of the water encapsulation device, the start-up time of the 2PNL vertical pump is reduced, and the annual power saving is 72900kW. h, saving more than 30,000 yuan. In summary, it can save 160,000 yuan in cost for concentrator every year.

Under the high pressure of environmental protection, good dust-proof treatment not only protects the environment, saves resources, but also reduces production costs, reduces the labor intensity of employees, and improves the efficiency of equipment.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia