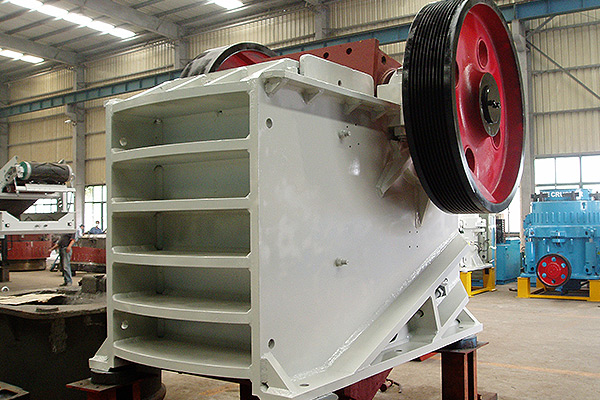

Main points of jaw Crusher repair and maintenance

Jaw crusher is widely used in mining, smelting, building materials, road, railway, water conservancy and chemical industry and other industries in the medium-sized crushing of various ores. The maximum compression strength of the crushed material is 320 MPA.

Jaw crusher is the main equipment in mining, should be used carefully, the maintenance method is as following:

Stop jaw crusher regularly, check the machine, check the internal wear of the machine, replace the worn parts in time and repair it. At the same time pay attention to the weight and size of the replacement parts, should use the parts based on original parts parameters.

Check the jaw crusher belt conveyor regularly. Jaw crusher belt conveyor indispensable in the stone production line. Regularly adjust the tension of the conveyor belt to ensure uniform force on the conveyor belt. When using double motors driven, the V -belts should be matched in groups so that the length of each group is the same. If it is found that the belt wear worn is serious, please replace timely.

Lubrication of mechanical parts. The jaw crusher uses Mobil motor special grease or 3 lithium base grease, adding the right amount of grease every 400 hours; open the shaft assembly to clean the bearing working 2000 hours; to replace the new bearing working 7200 hours .

In order to ensure the normal operation of the crusher, the planned maintenance must be carried out in addition to the correct operation, including the daily maintenance, the medium repair and the major repair.

Maintenance method of jaw Crusher

The main contents of minor repair includes the inspection and repair of the adjustment device, the high-speed discharge gap and the replacement of the worn lining plate. Repair the transmission part, lubrication system and replace the lubricating oil. The period of minor repair is about 1-3 months.

In addition to minor repairs work, mid-term repair includes replacement of thrust plate, lining board, inspection and repair of bearing pad, etc. The period of mid-term repair is generally 1-2 years.

In addition to all the mid-repair work, major repairs include replacement of eccentric shafts and moving jaw mandrel, casting of pasteurized alloy at the top of the connecting rod head, replacement or repair the worn parts. The major repairs period of jaw crusher is usually about 5 years.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia