Three major issues of crawler-type mobile crushing station

Crawler-type mobile crushing station is a kind of high efficiency crushing equipment, which adopts self driving mode, advanced technology and complete functions. There is a reader left a message in the background to ask editors about the crawler-type mobile crushing station. This article answers for you one by one.

1.What are the categories of crawler-type mobile shredding station?

Crawler-type mobile crushing station can be divided into four series: primary crushing, second crushing, third crushing and crushing. Primary machine are mainly jaw crusher and hammer crusher, it mainly used for handling large materials which are more than 30 cm. Second machine are mainly cone crusher and impact crusher, it mainly used to handle medium-sized materials which is under 30 cm. Third crushing are short head cone crusher, three cavity impact crusher and sand making machine, it mainly used for sand making and fine aggregate treatment. Screening station is an independent series, according to the type and output of the user to choose the number of layers and size of the screen.

2.What are the characteristics of crawler-type mobile crushing station?

a. It is easy to transport, self-movement and get on the trailer without adding concrete foundation.

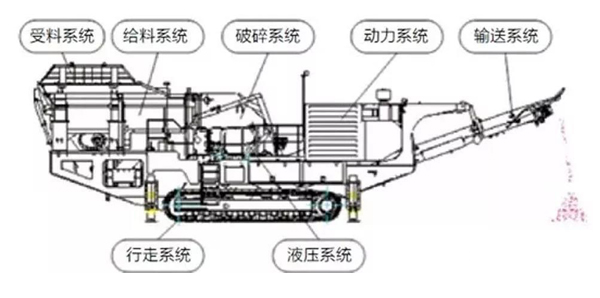

b. It integrates process equipment such as receiving, crushing and conveying. It has excellent crushing performance of rock crushing, aggregate production and open-cast mining through optimization of process flow. It can form a powerful crushing operation flow line through combination of different models to complete processing operations with multiple demands.

c.Fuel saving, fuel saving rate as high as 25%.

d.It can be used for climbing operation to meet the crushing requirements of mines, hydropower stations, coal mines and other projects.

3.Installation and maintenance of crawler-type mobile crushing station

a.Installation

(1).After installation, check whether the bolts at all parts are loose and whether the main engine compartment door is fastened. If so, please fasten it.

(2).Configure the power cord and control switch according to the power of the equipment.

(3).After the inspection, the no-load test run shall be carried out, and the production can be carried out after the test run is normal.

b.Maintenance

(1).Good lubrication has a great difference with bearing life, which directly affects the service life and operation rate of the machine. Therefore, the injected lubricating oil must be clean and well sealed. The main oil injection places of the machine are rotating bearing, roller bearing, all gears, movable bearing and sliding plane.

(2).The newly installed wheel hoop is easy to loose and must be checked frequently.

(3).Pay attention to check the wear degree of easily worn parts and replace the worn parts in time.

(4).The bearing cannot move on the underframe, resulting in a serious accident.

(5).If the bearing oil temperature rises, stop the machine immediately to check the cause and eliminate it.

(6).If there is any impact sound during the operation of the rotating gear,stop the machine for inspection immediately and eliminate.

Compared with all kinds of fixed crushing stations, the mobile crushing station is like a movable small and medium-sized crushing plant with advanced design, excellent performance, high production efficiency, convenient use and maintenance, economic operation cost and stable work.

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia