How to choose a high quality grinding mill?

The industrial powder milling industry is the sector involved in the manufacturing and processing of various materials, grinding them into powders or fine particles. This industry plays a crucial role in various fields, including pharmaceuticals, food processing, chemical engineering, materials science, metallurgy, and construction materials. Many ores can be used in industrial powder production, such as metal ores, non-metallic ores, and minerals (such as iron ore, copper ore, gypsum, talc, etc.), which are processed through grinding for applications in metallurgy and the preparation of construction materials.

There are various types of industrial powder milling machines suitable for different processing needs and material characteristics. Here are some common types of industrial powder milling machines:

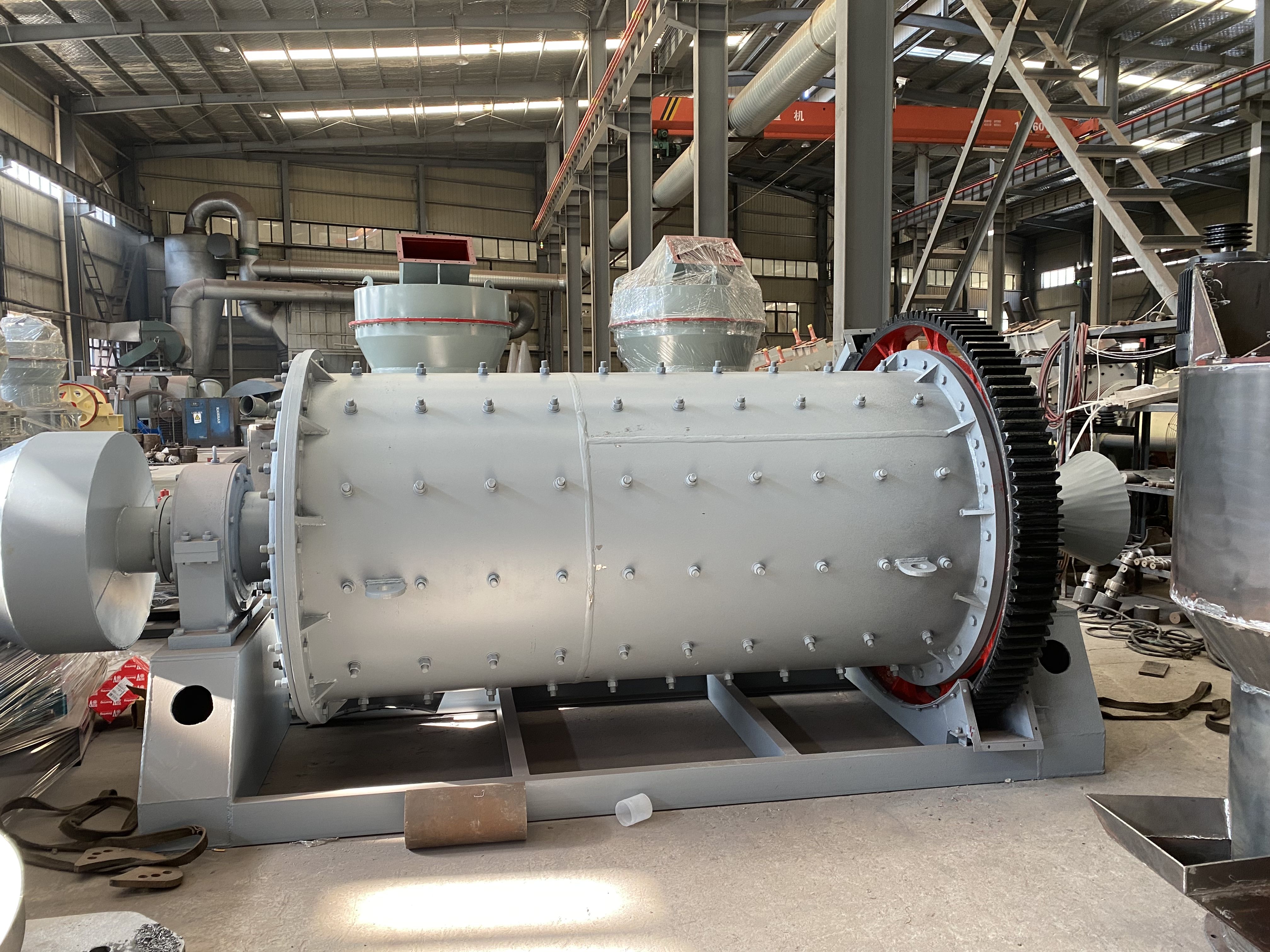

Ball Mills: Ball mills are one of the most common powder milling devices. They grind materials by placing grinding media in a rotating cylinder to crush the materials into powder. Ball mills are used for a wide range of materials, including ores, chemicals, ceramics, and granulated food products.

Vertical Mills: Vertical mills are arranged in a vertical orientation and are used to grind various materials such as coal, cement clinker, and ores. They are typically employed in large-scale industrial production.

High-Pressure Roller Mills: High-pressure roller mills use high-pressure rollers to crush materials into powder form. They are commonly used in processing ores and coal.

These are some of the common types of industrial powder milling machines, each with specific applications and advantages. Choosing the right milling machine depends on factors such as the characteristics of the raw materials, particle size requirements, production capacity, and yield. Different types of industrial powder milling machines can meet various processing needs.

Sandmine Machinery has rich experience on grinding mill manufacturing, we provide several kinds of grinding mill to meet different fineness and capacity demand, we can design suitable solution based on your exact demand, welcome to contact with us.

Next Page: How to confirm aggregates size and application

Prev Page: Introduction of ball mill application

Hot News

Recommended Case

- 550TPH Granite Aggregates Production Line in Henan

- 450TPH Limestone Gravel Production Line in Mexico

- 300TPH Feldspar Gravel and Sand Production Line in Gansu

- 200TPH Basalt Aggregate Production Line in Sri Lanka

- 300TPH Coal Gangue Crushing Production Line in Colombia

- 180TPH Waste Rock Crushing Production Line in Australia