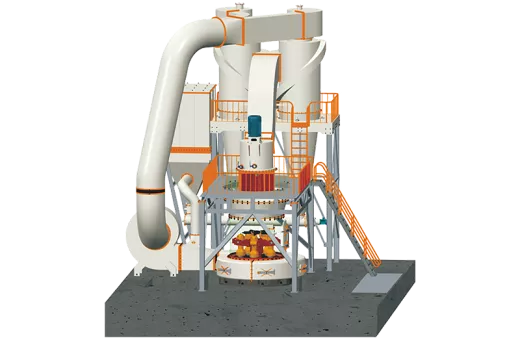

Calcite Grinding Line in Guangxi

Commissioning time : 2019

Location: Guangxi, China

Material: Calcite

Finished size: 325mesh

The project is located in an important producing area of calcite, the government attaches great importance to the development and utilization of calcite. After visiting more than ten manufacturers in China and abroad, the customer finally finalized Sandmine’s grinding mill. This grinding machine adopts advanced grinding technology, with high grinding efficiency, powder is also very pure; the optimized energy-saving design effectively reduced energy consumption and saved costs; Due to the closed grinding system, dust pollution is also low. The project has become a local benchmark.