100TPH Limestone Tailing Sand Making Production Line in Sichuan

Commissioning time : 2020

Location: Sichuan, China

Material: Limestone Tailing

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-40mm

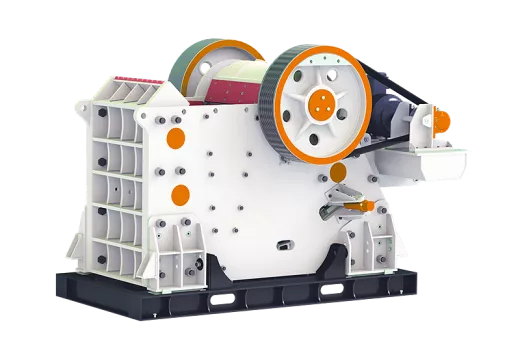

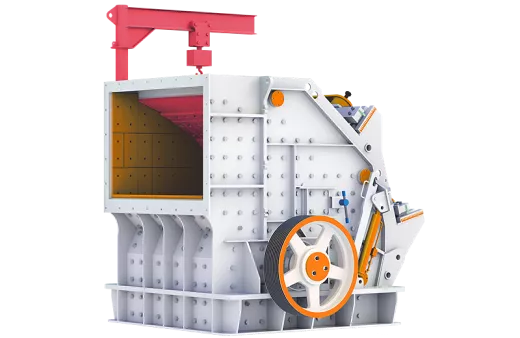

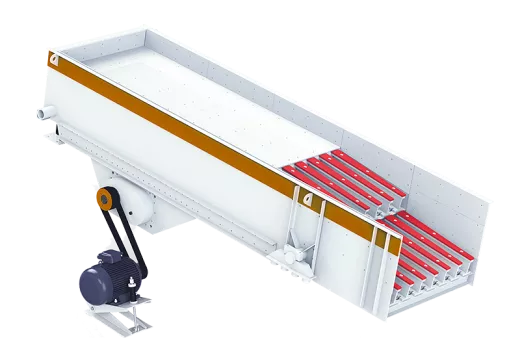

Sandmine has rich experience in making sand from tailings, which can effectively increase the added value of tailings. We provided customers with the classic configuration of jaw crusher + cone crusher + sand making machine, they are hot products of Sandmine, effectively improved the quality of finished aggregates and earned rich profits for customers. Sandmine use high quality equipment to help tailings recycling.