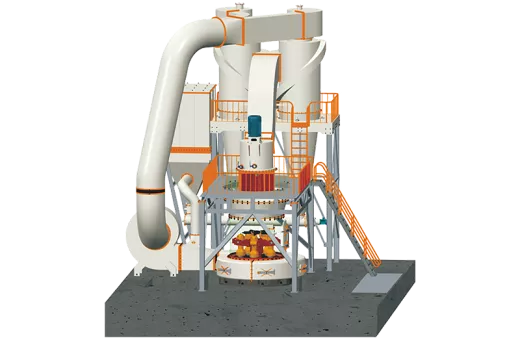

Coal Powder Manufacturing Line in Shanxi

Commissioning time : 2017

Location: Shanxi, China

Material: Bituminous coal

Finished size: 200mesh

When ball mill was previously used in this metallurgical plant, it faced the problem of huge noise and high power consumption. However, since using Sandmines’ grinding mill, these problems have been effectively solved. This grinding mill makes little noise, takes small areas, is easy to maintain, and the service is better. This makes the production process of the metallurgical plant more efficient, energy saving and environmental protection, while reduced the labor intensity of workers and improved production efficiency