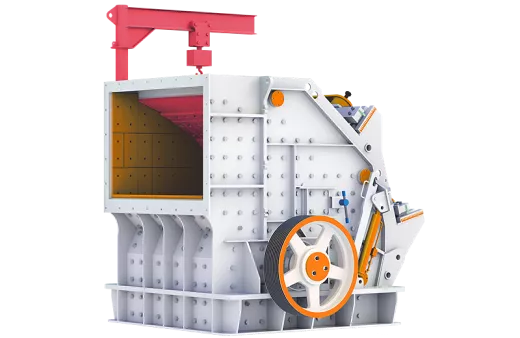

Petroleum Coke Grinding Line in Shandong

Commissioning time : 2016

Location: Shandong, China

Material: Sponge coke, Bullet coke

Finished size: 250 mesh

This glass factory use heavy oil as fuel, but after changing to petroleum coke, the calorific value is similar, the cost is reduced by half, the efficiency is also improved, and the emission of pollutants is less, the effect is very good. Sandmine provides all the equipment and design solution for the whole process. The customer are very satisfied with Sandmine product quality, operation performance, cost control and after-sales service.