230TPH Granite Aggregate Production Line in Laos

Commissioning time : 2014

Location: Laos

Material: Granite

Finished size: 0-5mm, 5-16mm, 16-31.5mm

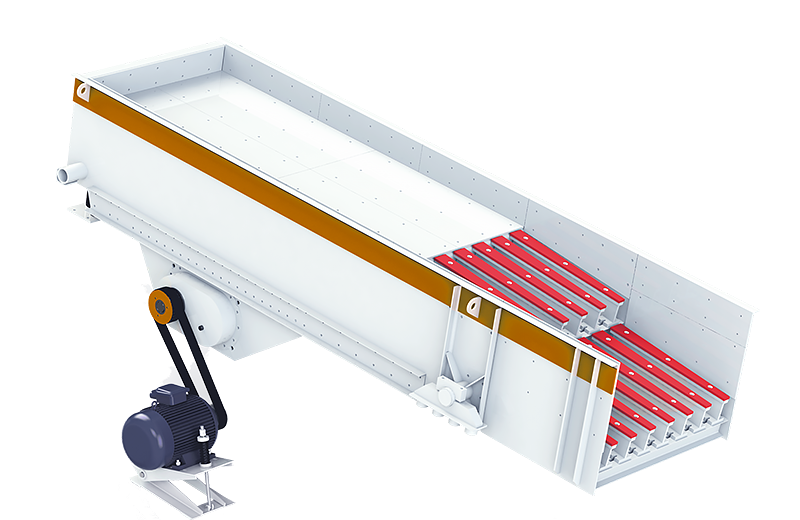

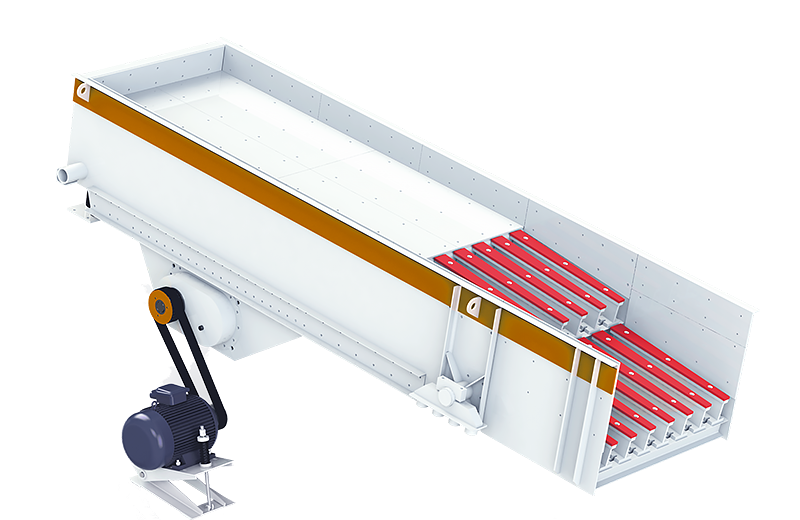

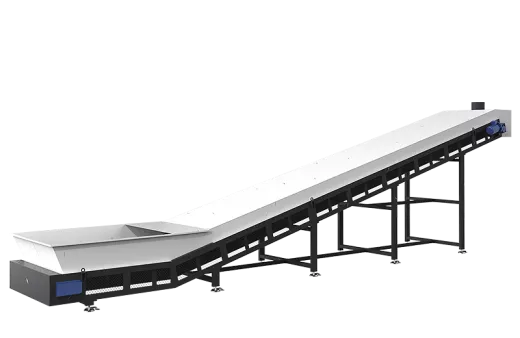

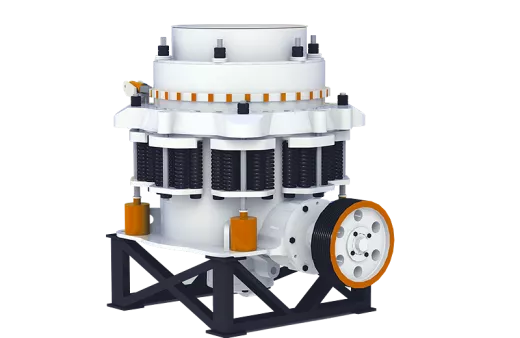

Our company is fully responsible for the design, equipment manufacturing, installation and commissioning and spare parts supply for the whole project, which greatly reduced unnecessary investment. Using advanced multi-cylinder full hydraulic cone crusher, layer crushing brings good products shape, full hydraulic control is accurate and reliable, equipment maintenance is convenient, finished products does not need to be shaped, low operating costs, low failure rate for many years of operation.