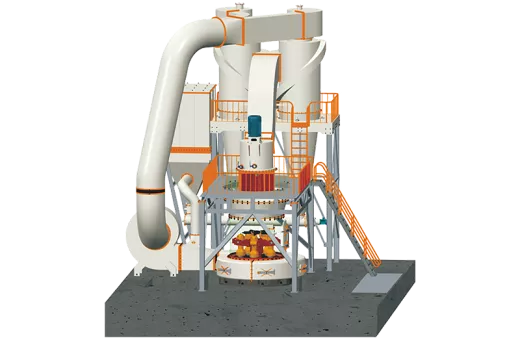

Gypsum Powder Production Line in Ningxia

Commissioning time : 2017

Location: Ningxia, China

Material: Gypsum

Finished size: 325 mesh

The hardness of gypsum is relatively small, and it is relatively easy to process, but the grinding roller of the traditional grinding equipment needs to add butter once every 24 hours, the maintenance is more troublesome. After the recommendation of Ningxia Gypsum Industry Research Institute, the customer contacted Sandmine. After site inspection of the equipment production site and engineer’s introduction, it is learned that Sandmine heavy duty grinding mill roller can work continuously for 30 days after adding oil, which greatly reduced the maintenance cost and time. The Customer decide to cooperate with us quickly based on the recognition of our company's equipment technology.