GSDF series German type super fine roller mill is a high-end super fine grinding mill adopted German technology and standards. It has been successfully applied to the deep processing of super fine powder of heavy calcium carbonate, kaolin, limestone, dolomite, barite and other materials. It helps industrial production of aerospace stealth materials, advanced ceramics, wave absorbing materials, functional fibers, environmental protection materials, biomedical materials and other high-tech industries.

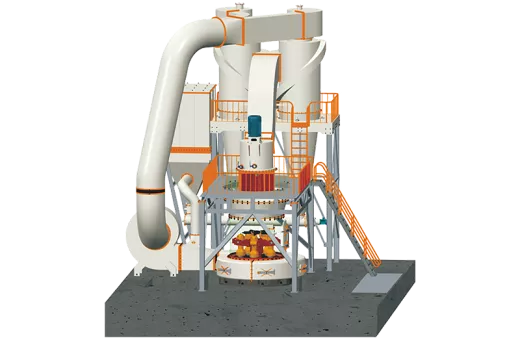

GSDF series German type super fine roller mill includes the main mill, powder separator, double cyclone powder collector, pulse bag dust collector, high pressure blower, motor, pipe and muffler, optional equipment includes jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet.

The bulk material is broken into small particles by the crusher and sent to the storage bin by elevator, the electromagnetic vibration feeder evenly sends the material to the middle of the upper rotary table, the material is scattered under the action of centrifugal force and falls into the raceway of the grinding ring, then the roller grinds the material, the material will be grinds by the three layer rollers. The suction effect of the high-pressure centrifugal blower inhales the external air into the machine, and brings the coarse powder after the third layer grinding into the powder separator. The spiral flow generated by the rotating worm wheel in the powder separator makes the coarse material fall back and be re-grinded, the fine powder enters the cyclone powder collector with the air flow and is discharged by the discharge valve at the lower part of the cyclone powder collector as the finished products, the air flow with small amount fine dust is purified by the pulse dust collector and discharged by the blower and silencer.