GLMF series German type super fine vertical mill is a large grinding equipment with advanced technology and excellent performance, which integrates grinding, drying, powder selection and conveying. It adheres to the advanced powder making technology and versatility, adopts reasonable and reliable structural design, and conforms to the advanced technological process, the main technical and economic indicators have reached to international advanced level.

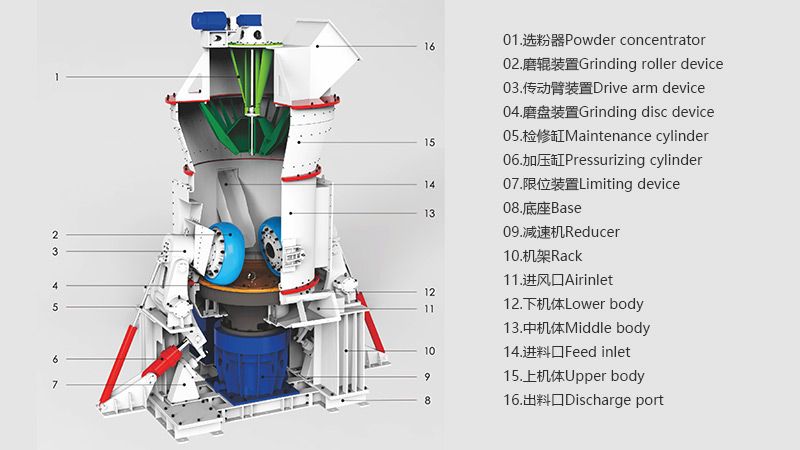

GLMF series German type super fine vertical mill is composed of transmission device, grinding roller and grinding disc, grading device, pressurizing and lubricating device, housing and frame. The main motor drives the mill plate to rotate through the reducer, while the hot air enters the vertical mill body from the inlet, the material falls from the feeding port to the center of the mill plate and moves evenly from the center of the mill plate to the edge under the action of centrifugal force. When it passes through the roller grinding area, the large material is directly crushed by the mill roller, and the fine material is extrudated to form a material bed for materials self-crushing. The crushed materials continue to move to the edge of the mill until it is taken away by the strong air flow at the wind ring, while the larger size material falls to the mill again and continues to be crushed. When the material in the air flow passes through the upper separator, under the action of the rotor blade, the coarse particles return to the mill, and the qualified fine powder with the air flow is collected and discharged by system's powder collector. When the debris such as the iron block mixed in the material moves to the edge of the mill, it falls to the lower chamber of the mill due to its own weight, and is discharged by the scraper installed at the bottom of the mill.