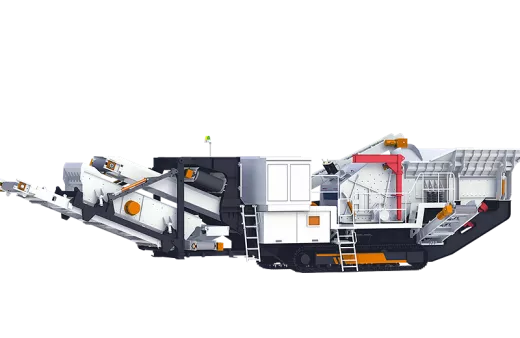

150TPH Crawler Type Mobile Granite Aggregate Production Line in Shanxi

Commissioning time : 2012

Location: Shanxi, China

Material: Granite

Finished size: 0-5mm, 5-16mm, 16-31.5mm

The customer inspected more than ten manufacturers, and after careful comparison, finally decided to use the crawler mobile crushing station series products of Sandmine. The process design of the production line is reasonable and simple, and the commissioning and construction cycle is particularly fast, which is unmatched with the fixed production line. The main equipment is Sandmine advanced crusher, hydraulic adjustment, intelligent control, safe and efficient. Since the production, the line had high and stable production, widely praised, and often borrowed by other customers to use.