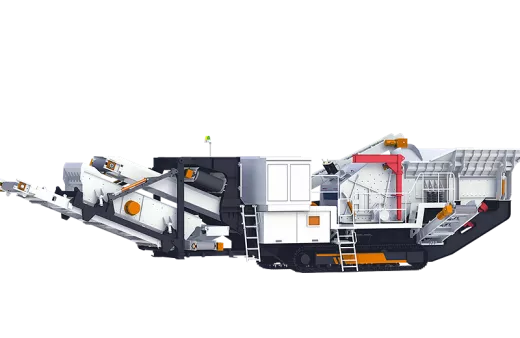

100TPH River Stone Sand Manufacturing Line in Tajikistan

Commissioning time : 2017

Location: Tajikistan

Material: River stone

Finished size: 0-5mm, 5-10mm, 10-31.5mm

According to the actual needs of customers, Sandmine sent engineers to survey the field, and integrated the opinions of many parties, and configured an economic, environmental protection and low consumption sand production line. The production line has advanced technology, mature process and reliable performance equipment, with advantages of high efficiency, big capacity, good quality final products, not only to meet the customer's requirements of high-quality aggregate, but also to create considerable economic benefits for customers. After years of operation, it is still capable.