VIC Series Vertical Shaft Impact Crusher is a high-performance sand making equipment developed and produced with the introduction of German advanced technology, which plays an irreplaceable role in ores’ fine crushing and shaping. This series of products set two crushing modes (stone to stone, stone to iron) in one, can run continuously for 720 hours without stopping, coupled with low investment costs, excellent finished product shape, has now become the main equipment in sand making industry.

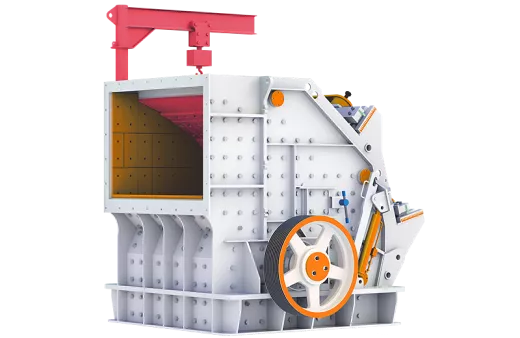

VIC Series Vertical Shaft Impact Crusher is composed of the upper part of the body, the lower part of the body, the top cover rotating device, the crushing chamber part, the rotor part, the bearing transmission part, the motor transmission assembly, the support assembly and the lifting device assembly.

Stone to stone crushing method, mainly used in the stone shaping: The motor drives the bearing cylinder to drive the main shaft to rotate at a high speed while the rotor rotates at a high speed along with the main shaft. Materials entering the impeller are accelerated by the impeller and then sprayed into the crushing chamber, where they collide with the lining materials formed in the crushing chamber and interact with each other to transform the kinetic energy obtained after the material acceleration into the energy required for crushing or shaping materials. The material that circulates several times in the crushing chamber is broken and shaped many times under the action of the surrounding gas eddy, so as to realize the continuous crushing and shaping of the material, and the required finished material is discharged from the lower part of the body.

Stone to iron crushing mode is mainly applicable to the crushing workplace: when the material is ejected from the rotor, it impinges on the impact block installed in the crushing chamber, and converts the energy obtained by material accelerating to the energy required for crushing. After the impact, the material is directly discharged from the lower part of the body, and multiple cycle crushing in the crushing chamber cannot be realized.