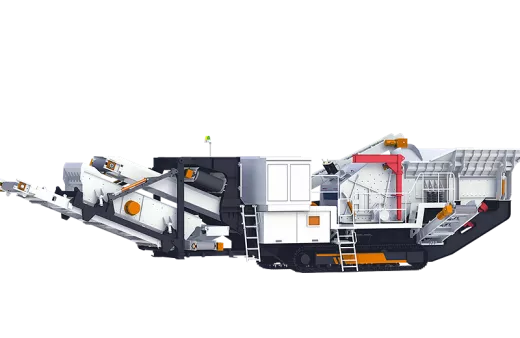

1 Million Tons per Year Construction Waste Processing Line in Beijing

Commissioning time : 2015

Location: Beijing, China

Material: Construction waste

Finished size: 0-5mm, 5-10mm, 10-31.5mm

Sandmine provides us technical solution and full set construction waste treatment equipment, fully enclosed production workshop can realize effective noise and dust reduction, to achieve green production. On the one hand, it solved the problem of construction waste piling around the city, and on the other hand, the quality of recycled aggregate is very good, which is used for the construction material of highways and airport runways, which is really too environmentally friendly.