600TPH Limestone Aggregate Production Line in Qinghai

Commissioning time : 2015

Location: Qinghai, China

Material: Limestone

Finished size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

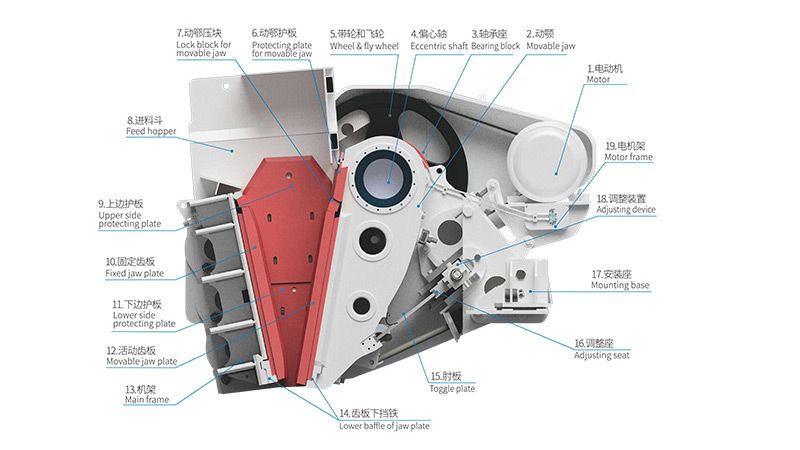

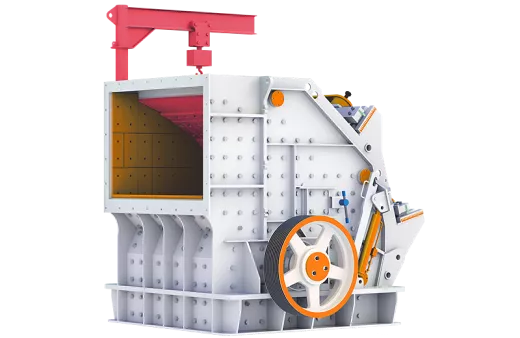

The customer is a well-known local stone process factory, and the processed stones are supplied to local roads, railways and infrastructure construction, the demand is large. Our company configured a number of different models of JCH series European version jaw crusher, the crushing ratio is large, with high production efficiency, the capacity can fully meet customers’ needs. In addition to the full set of production line equipment, we also provide customers with free installation guidance, equipment testing, operation training and spare parts supply and other services.