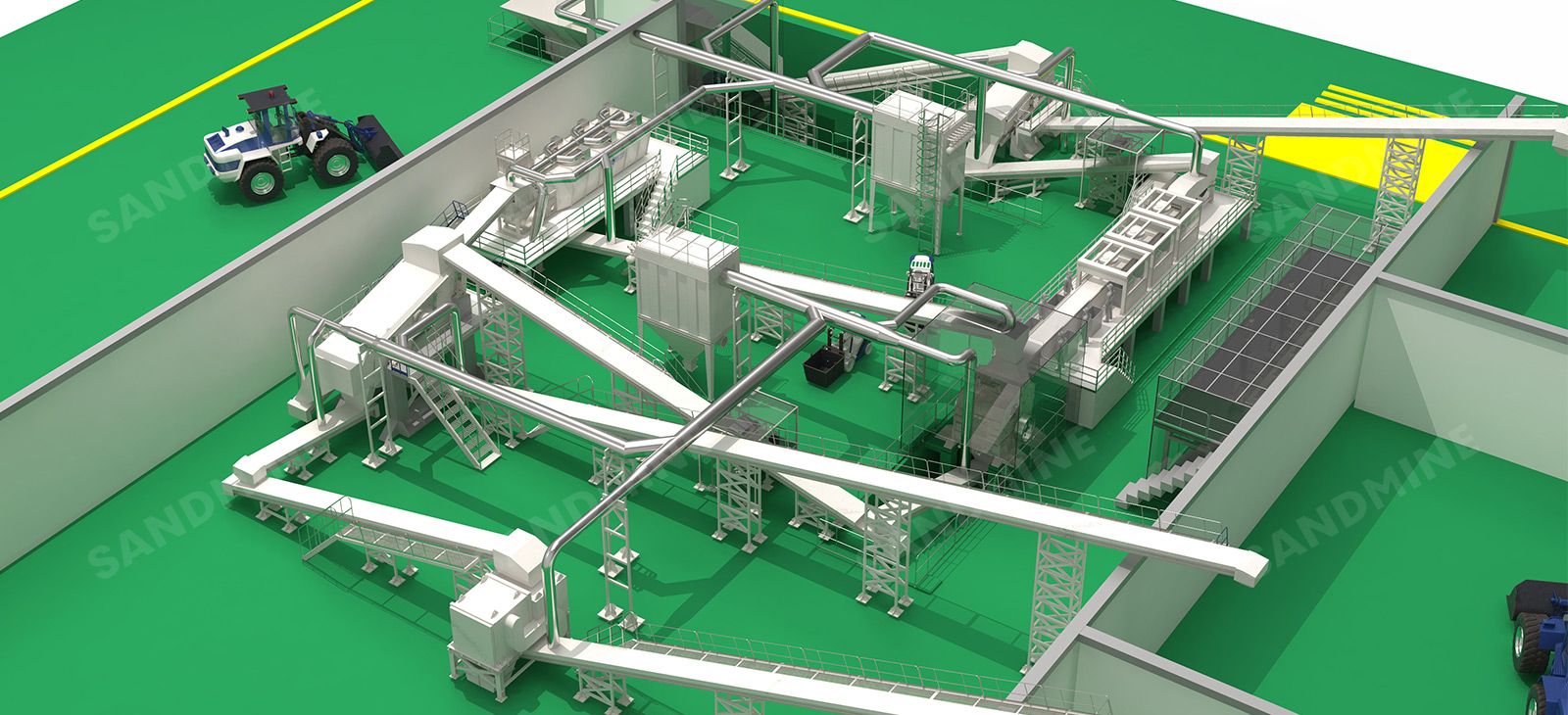

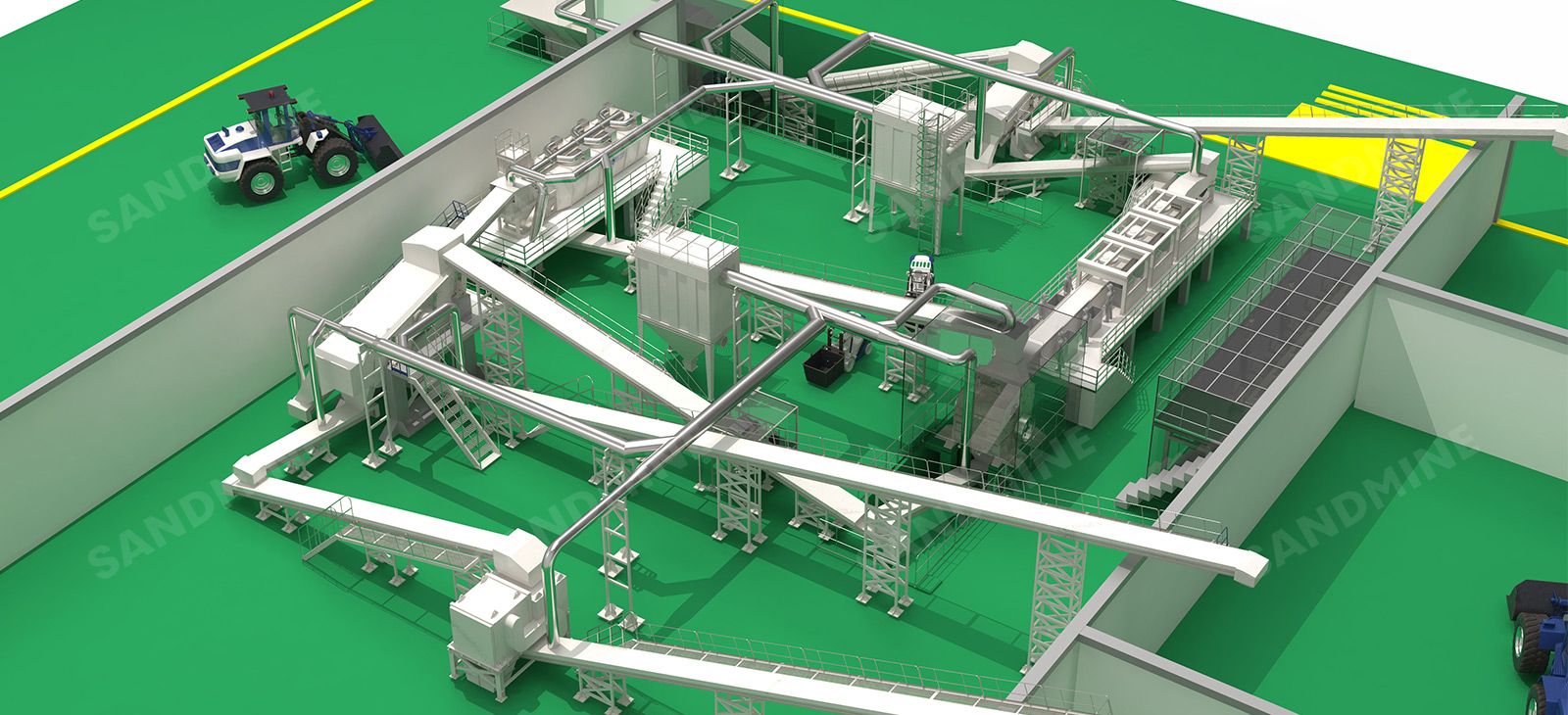

This solution is suitable for fixed type construction waste disposal

With the acceleration of urbanization, solid waste disposal has become a serious environmental problem. Proper disposal of solid waste has great significance for protecting environment and saving resources. The solid waste disposal solutions provided by Sandmine not only covers all kinds of solid waste such as construction waste treatment, waste stone treatment, tailings treatment, and cave slag treatment, but also pay attention to the balance of environmental protection and economic benefits, strive to maximize the resources utilization.

In the process of solid waste disposal, the process and equipment provided by Sandmine can ensure the efficient and safe treatment of solid waste. According to different type of solid waste, we adopt corresponding treatment methods. For example, construction waste can be made to reusable aggregates, concrete material through crushing, screening, sorting process; Waste rock, tailings, cave slag can be made to sand, mineral powder and other high value products through crushing, grinding and other processes.

Sandmine has a strong technical team and advanced mining equipment, we provide customized solution according to different customer needs, to ensure efficient treatment while reduce the pollution to environment, to achieve resources recycling. In addition, Sandmine provides one-stop service on project planning, process design, equipment selection, installation and commissioning, and after sale service.

This solution is suitable for fixed type construction waste disposal

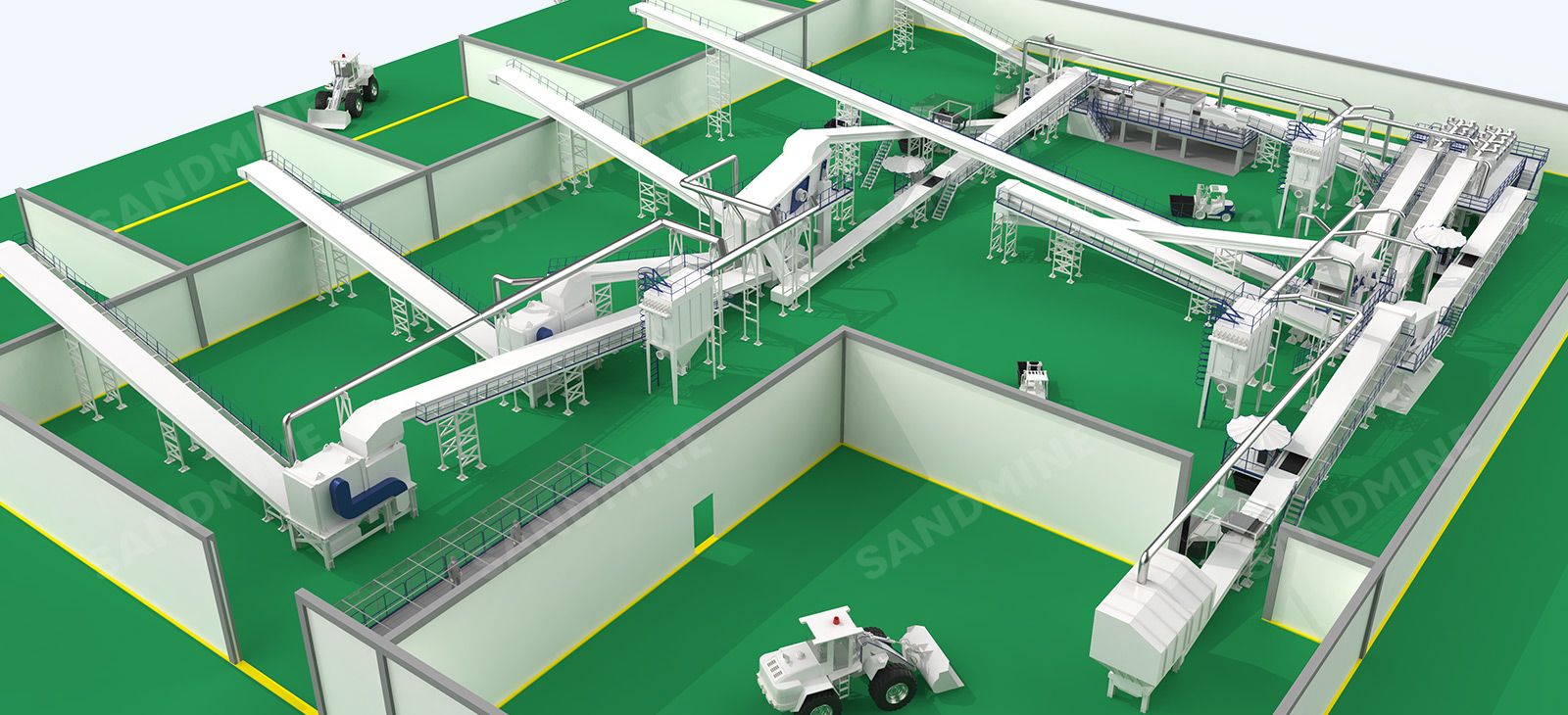

This solution is suitable for mobile type construction waste disposal

This solution is suitable for fixed type demolition waste disposal

This solution is suitable for the tailings and waste rock in high compressive strength

This solution is suitable for the tailings and waste rock in low compressive strength

This process is for reference only. Depending on different material, usage and discharge size, we can customize the process and configure appropriate equipment for you.

Material disposal plan

Construction waste refers to the muck, waste soil, waste material, silt and other wastes generated during the construction, laying, demolition and repair of various buildings, structures and pipe networks by construction units or individuals. According to the composition, construction waste can be divided into slag, concrete blocks, gravel blocks, brick fragments, waste mortar, mud, asphalt blocks, waste plastics, waste metal, waste wood and so on. After sorting, crushing, recycling, most of the construction waste can be reused as renewable resources. For example, brick, stone, concrete can replace sand, plastic, fabric, wood furniture and other combustible materials can be made into fuel rods for power plants.

Demolition waste refers to the discarded materials or wastes generated by residents and business units in the process of houses decoration, including concrete, mortar, brick, ceramic, stone, gypsum, aerated concrete blocks, metal, wood, glass, paper, cloth and plastic. Demolition waste can be used as resources: concrete waste and ceramics can be used as roadbed materials for road construction; bricks and stone can be used as raw materials for sintering bricks; gypsum can be used as filler; aerated concrete blocks can be used to make wall materials or insulation materials; metal can be smelted into recycled metal; combustible light materials such as wood, paper, cloth and plastic can be processed into alternative fuels.

The surrounding rock of ore body and clasp stone with no industrial value produced in the process of mining is collectively referred to as mine waste rock. For pit mining, it is the rock separated by tunnel excavation and mining exploding that can not be used as ore. For open pit mines, it is the surrounding rock or clasp stone peeled off from the mineral deposit. Generally, pit mining (underground mining) will produce 2-3 tons waste rock when take 1 ton ore, and open pit mining will peel off 6-8 tons waste rock when take 1 ton ore. Mine waste rock can be used to produce sand aggregate, concrete fine aggregate, as filler, extract iron, copper and other metals.

Tailings is the solid waste discharged after the ore is ground and the "useful components" are selected by the concentrator under specific economic and technical conditions, that is the solid waste containing few target metals remaining after the ore is sorted, which contains a certain amount of useful metals and minerals. In general, 0.5-0.95 ton tailings can be produced for dealing every 1 ton ore. Tailings are with high using value, and can be used as coarse and medium size aggregates, used in low-strength commercial concrete or asphalt concrete, building materials, or to recover valuable metals and minerals from them.

Cave slag, as the name suggests, it is the waste slag in the cave, generally refers to the stone waste excavated in some tunnel projects, which belongs to the material that must be abandoned. Because of its strength, cave slag can be used as backfill, so most tunnel projects will sell such materials to relevant units, departments or other project for waste utilization. Cave slag can also be used to make sand and stone aggregate, such as the famous Sichuan-Tibet railway needs 200 million tons of sand and stone aggregate, and generated 240 million square cave slag, rational use of waste cave slag to prepare aggregate in the mountain area will reduce project cost.

Please fill in the form with your information and specific needs, which will help us to get in touch with you as soon as possible and provide you suitable solution and a reasonable equipment quote.