SANDMINE

Stone Crushing Stand-alone Equipment

and Production Line Plan

Zhengzhou Sandmine Machinery Co., Ltd is a large-scale stone crushing equipment manufacturing enterprise that integrates R&D, production, sales and service for the global mid-to-high-end mining, construction, and aggregate markets. Company's main products include stone crushing equipment, stone sand making equipment, mobile crushing equipment and supporting equipment, and can provide customers one-stop solution for sand and gravel aggregate production, metal ore crushing, construction waste treatment, tailings&waste rock crushing, etc. With reliable product quality, excellent innovation capabilities, extensive sales network and perfect service system, we have won the trust and praise from worldwide customers.

CRUSHING PRODUCT

Stone Crushing Equipment

Stone crushing equipment crush various ore rocks to the required size through extrusion, impact and other crushing principle.

Dozens of models of jaw crusher, impact crusher and cone crusher can meet various needs of customers.

JCH series European Type Jaw Crusher

Output size: 40-300mmCapacity: 16-1150TPH

JCH series European jaw crusher is successfully developed a new generation of product, which used international advanced crushing technology and research results, is based on many years of experience in the design and manufacture of jaw crusher, used finite element analysis method. Which is suitable for crushing compressive strength is not higher than 320Mpa of various ores and rocks. Thanks to its excellent performance, it has become a very popular equipment in the world, and it is also the preferred choice for the primary crushing of hard wear-resistant materials.

GIC Series Impact Crusher

Output size: 20-100mmCapacity: 80-700TPH

As the main equipment for the production of high specification aggregates, GIC series impact crusher is very suitable for coarse crushing, medium crushing and fine crushing operations of various soft and medium hard ores. Large size crushing chamber, heavy rotor design make GIC series impact crusher not only with high production efficiency, widely used, and truly create more value for customers.

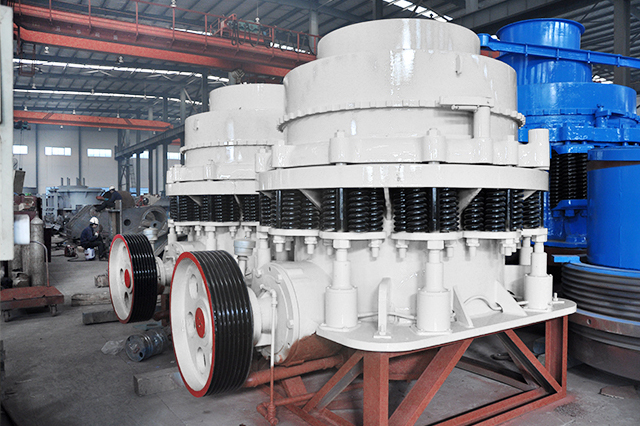

GHP Series Multi Cylinder Cone Crusher

Output size: 13-63mmCapacity: 95-1028TPH

GHP series multi cylinder cone crusher is a new hydraulic cone crusher with superior performance developed by our company with the introduction of German advanced technology. The equipment can be widely used in metal and non-metal mines, cement plants, construction, metallurgy and other industries, and can efficiently complete a variety of medium crushing, fine crushing, ultra-fine crushing operations, stable performance, easy to maintain make it to be an ideal product to replace spring cone crusher and general hydraulic cone crusher in modern mining, construction industry.

GHS Series Single Cylinder Cone Crusher

Output size: 10-130mmCapacity: 40-1200TPH

GHS series single cylinder cone crusher is a cone crusher with the world's advanced level, not only has high reliability, but also with high crushing efficiency, low operating cost, good product particle shape and other advantages, widely used in mining and aggregate industry, suitable for crushing hard, medium hard minerals and rocks, can be used in the material coarse、 fine and ultra-fine crushing.

GHY Series Cone Crusher

Output size: 3-64mmCapacity: 27-725TPH

GHY series cone crusher is an efficient spring cone crusher that combines advanced technology to optimize and improve the traditional spring cone crusher. It strictly follows the concept of more crushing and less grinding on the principle of layer crushing. It is suitable for crushing all kinds of ores and rocks with medium and above hardness. Independent thin oil lubrication system, multiple control units make it safe and reliable. The type of crushing chamber depends on the feeding size and the final needed size.

Stone Sand Making Equipment

Sandmine not only produces a variety of efficient sand making equipment, such as sand making building, vertical shaft impact crusher, compound crusher, hammer fine crusher, but also supplies fine sand separation, recovery, cleaning equipment, to form a complete sand making industry chain with crushing equipment.

Sand Making Building

Feed size: ≤600mmCapacity: 60-300TPH

SGL, SSL series sand making building adopts dry sand making process and building layout, which is composed of six parts: Feeding, sand making, finished product discharge, dust removal, stone powder storage and electrical control. The sand making system is the core part of the entire process, raw materials are crushed, shaped, screened, graded and humidity controlled in this process. The whole system covers small area, the produced sands with advantages of round shape, reasonable grade, controllable powder content, so the sales market is very good.

VIC Series Vertical Shaft Impact Crusher

Feed size: 35-50mmCapacity: 60-683TPH

VIC series vertical shaft impact crusher is a high-performance sand making equipment developed and produced with the introduction of German advanced technology, which plays an irreplaceable role in ores’ fine crushing and shaping. This series of products set two crushing modes (stone to stone, stone to iron) in one, can run continuously for 720 hours without stopping, coupled with low investment costs, excellent finished product shape, has now become the main equipment in sand making industry.

GVIC Series Complex Vertical Impact Crusher

Output size: 0-3mm (70%-90%) Capacity: 8-80TPH

GVIC series complex vertical impact crusher is a new high efficiency fine crushing equipment which combined domestic and foreign fine crushing technology and the design is based on material input energy increase gradually and graded crushing principle. It has advantages of large production capacity, high crushing efficiency, large crushing ratio, small abrasion, low energy consumption, good sealing, smooth operation, easy maintenance and other outstanding advantages. When it is used in building materials enterprises to crush limestone, coal, coal gangue, cement clinker and other materials, it can significantly reduce the particle size before grinding and increase the mill capacity, is an ideal energy-saving crushing equipment.

PCX Series High Efficient Hammer Fine Crusher

Output size: 3-10mm Capacity: 15-310TPH

PCX Series high efficiency hammer fine crusher is a new generation of high efficiency crusher designed and manufactured by absorbing advanced German technology, optimized design and structure. It is suitable for crushing limestone, marl, sandstone, shale, gypsum, coal and other raw materials with compressive strength not exceeding 200MPa. The machine has a large crushing chamber and feed opening, which is suitable for the smooth entry of large ores, has the characteristics of large crushing ratio, uniform product particle size, reliable work, easy maintenance, economic operating costs and so on.

Mobile Crushing Equipment

All kinds of crushing and screening equipment can be freely combined, and equipped with Sandmine's crawler or wheel type frame to achieve flexible access to complex and rugged work sites, without foundation installation, quickly start the operation mode, and also with high hedging rate.

GC-J Series Crawler Jaw Crushing Plant

Output size: 70-200mmCapacity: 140-600TPH

GC-J series crawler jaw crusher plant is a kind of multi-purpose, compact and modular crawler type mobile crushing station designed with advanced German mobile crushing technology, it can fully meet customers' requirements for high capacity, high mobility and high reliability of crawler type mobile crushing station. It integrated efficient crushing technology and automated control technology, which can be operated in different environment, especially in rough road sections and climbing operations, suitable for primary crushing needs of a variety of materials.

GC-I Series Crawler Impact Crushing Plant

Output size: 20-150mmCapacity: 150-400TPH

GC-I series crawler impact crusher plant combines the characteristics of crawler mobile crushing station and impact crusher, it has the advantages of high mobility, high reliability, high production capacity and low maintenance cost, can meet various material crushing needs. It uses impact crusher as main crushing equipment, crushing ratio is large, crushing efficiency is high, and energy consumption is low. At the same time, because of the crawler mobile platform, it can be easily moved and operated in different locations, which is suitable for crushing operations in various complex environment.

GC-C Series Crawler Cone Crushing Plant

Output size: 10-45mm Capacity: 100-450TPH

GC-C series crawler cone crusher plant is an advanced mobile crushing station, which has the advantages of high efficiency, flexibility and convenience. It usually works with the coarse crushing equipment mobile jaw crushing station to achieve multi-stage crushing of large materials to meet different needs. The crawler type mobile cone crushing station is mainly composed of crawler chassis, transmission device, cone crusher, feeding device, vibrating screen, hopper, belt conveyor, etc. Cone crusher is the core crushing equipment, uses advanced crushing technology, can achieve high efficiency, low consumption crushing operation. The crawler chassis and transmission device provide flexible and convenient mobility.

GC-S Series Crawler Screen Plant

Capacity: 85-350TPH

GC-S series crawler screen plant adopts advanced screening technology, which can realize automatic and high-precision screening. It is composed of screening device, track walking device, hydraulic system, electrical system and other parts. Among them, the screening device is core part, which uses high-precision screen and advanced vibration device to achieve efficient and accurate screening; The crawler walking device can make the equipment move freely under various terrain conditions and adapt to different working environments; The hydraulic system provides stable and reliable driving power to ensure the equipment normal operation; The electrical system is responsible for the automatic control and monitoring of the equipment to ensure the stability and safety of the equipment.

GW-J Series Wheeled Jaw Crushing Plant

Output size: 65-275mm Capacity: 90-650TPH

GW-J series wheeled jaw crusher plant is a mobile crushing equipment composed of feeding, crushing, screening, conveying and other systems, which plays an important role in construction waste, mine crushing and other fields. Mobile type jaw crusher station can avoid foundation construction and auxiliary machine installation, can work upon arrival at the site, greatly shortened the construction time and effectively reduced the investment cost. Its outstanding advantage is the efficient crushing capacity. The main crushing equipment adopts the jaw crusher independently developed by Sandmine Machinery, which has super crushing power and ultra-high crushing efficiency, can meet the crushing demand of various metal and non-metallic ores.

GW-I Series Wheeled Impact Crushing Plant

Capacity: 80-300TPH

Compared with the traditional fixed crushing production line, GW-I series wheeled impact crusher plant has unique design and solid shape, and can be widely used in ore crushing, engineering construction, construction waste disposal and other fields, it can process materials nearby, greatly expanded the crushing working site. Impact crusher is the core machine which is equipped with heavy rotor, heavy load bearing, large crushing chamber, it can achieve high capacity and large crushing ratio in second and third crushing stage. It has compact structure, easy to transport and install, and is highly praised in the field of medium and fine crushing operation.

GW-C Series Wheeled Cone Crushing Plant

Capacity: 50-320TPH

GW-C series wheel type mobile cone crusher station integrates cone crusher, vibrating screen and conveyor on a tire frame, which is mainly used in secondary or tertiary crushing and screening, is suitable for the stones mobile crushing operation in highway, railway, hydropower project. The main crushing system can freely choose single cylinder, multi-cylinder, full hydraulic cone crusher produced by our company, which shows good crushing effect and excellent finished products size when dealing with variety of medium and high hardness, medium and high abrasive materials.

When working, the material is sent to the cone crusher by feeder, the crushed material falls into the belt conveyor and is sent out by vibrating screen, the qualified material is sent out by belt conveyor, and the unqualified large material is directly returned to the cone crusher for re crushing until the size is qualified.

STONE CRUSHING SOLUTION

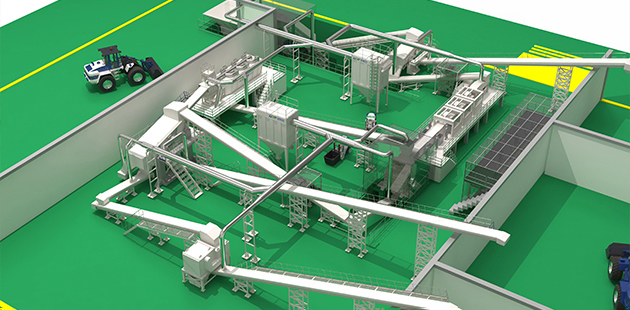

Sand&stone Aggregates Making Solution

The production process of sand&stone aggregates making includes feeding, crushing, screening, conveying and other links. In crushing process, it is necessary to choose appropriate crushing equipment according to different ore characteristics and engineering needs, such as jaw crusher, cone crusher, impact crusher, sand making machine and so on. In addition, the quality of sand and aggregate needs to be strictly controlled in the production process to ensure it meets the engineering requirements.

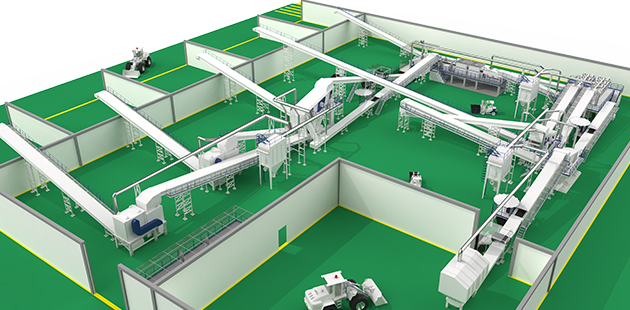

Metal Ore Crushing Solution

There are many different crushing processes depending on ores’ type, features and size demand. Generally, two-stage crushing process with coarse crushing + medium crushing or three-stage crushing process with coarse crushing + medium crushing + fine crushing is used. Coarse crushing use jaw crusher, medium and fine crushing use cone crusher or impact crusher. After multistage crushing, the final metal ore size is suitable for ball mill working, meeting the principle of "more crushing and less grinding".

Construction & Demolition Waste Disposal Solution

Construction & demolition waste composition is complex and irregular, in addition to gravel, brick, concrete blocks and other stone, there are metal, wood, cloth, plastic and other debris, so construction & demolition waste disposal production line equipment selection needs to be determined according to the actual project, generally through crushing, screening, sorting and other treatment, construction waste can be turned into treasure.

Tailings and Waste Rock Crushing Solution

Tailings is the solid waste discharged after the ore is ground and the "useful components" are selected by the concentrator under specific economic and technical conditions. Waste rock is surrounding rock of ore body and clasp stone with no industrial value produced in the process of mining。These tailings and waste rock is very valuable, through crushing, grinding and other processes, can produce sand aggregate, concrete fine aggregate, and extracting iron, copper and other metals.

STONE CRUSHING PROJECT CASE

Beijing 1 million tons per year construction waste crushing production line

Processed materials: Construction waste

Output: 1,000,000TPY

Project Introduction:

Sandmine provides us technical solution and full set construction waste treatment equipment, fully enclosed production workshop can realize effective noise and dust reduction, to achieve green production. On the one hand, it solved the problem of construction waste piling around the city, and on the other hand, the quality of recycled aggregate is very good, which is used for the construction material of highways and airport runways, which is really too environmentally friendly.

Shanxi 150TPH granite crawler type mobile crushing production line

Processed materials: Granite

Output: 150TPH

Project Introduction:

The customer inspected more than ten manufacturers, and after careful comparison, finally decided to use the crawler mobile crushing station series products of Sandmine. The process design of the production line is reasonable and simple, and the commissioning and construction cycle is particularly fast, which is unmatched with the fixed production line. The main equipment is Sandmine advanced crusher, hydraulic adjustment, intelligent control, safe and efficient. Since the production, the line had high and stable production, widely praised, and often borrowed by other customers to use.

Mongolia 500TPH iron ore crushing production line

Processed materials: Iron ore

Output: 500TPH

Project Introduction:

Due to the trust to Chinese machinery manufacturing enterprises, customers chose Saandmine after inspecting a number of manufacturing enterprises. We specially sent engineers to Mongolia for field survey, give a reasonable production line configuration. Three sets of different models of same series multi-cylinder cone crusher is bright spot of this project. The customer give high praise to the full hydraulic insurance system, lubrication system and discharge port adjustment, saving time and labor and safer. At present, the production line is very stable.

Sichuan 100TPH limestone tailing sand making production line

Processed materials: Limestone tailings

Output: 100TPH

Project Introduction:

Sandmine has rich experience in making sand from tailings, which can effectively increase the added value of tailings. We provided customers with the classic configuration of jaw crusher + cone crusher + sand making machine, they are hot products of Sandmine, effectively improved the quality of finished aggregates and earned rich profits for customers. Sandmine use high quality equipment to help tailings recycling.

STONE CRUSHING EQUIPMENT DELIVERY

Before equipment delivery, we ensure the following action:

-

Strict comprehensive inspection is made according to the quality standard, to ensure the high quality of each equipment.

-

Inspect the equipment model, quantity and spare parts one by one based on the contract, to ensure no fault.

-

Check the model and quantity again after packing, ensure no omission.

INDUSTRY KNOWLEDGE

-

Granite is a hard and durable igneous rock known for its unique crystal structure and diverse colors. It is used in construction, decoration, and sculpture due to its exceptional durability, capable of withstanding various natural environmental impacts. Granite is widely distributed, with major production areas in Europe, Asia, Africa,…

-

On October 17, Indonesia International Daily reported that Indonesia president Joko Widodo say Indonesia plans to build more high way and try to finish 1200 kilometers high way by 2019. He says that there must have high way from west to east in java island, also in Sumatra island, Kalimantan, Sulawesi island. According to Indonesia…

-

Selecting the appropriate jaw crusher for your mining, construction, or quarrying operation is a crucial decision that can significantly impact the efficiency and productivity of your process. With a myriad of options available in the market, it's essential to carefully consider various factors to ensure you make an informed choice. The…

-

Recently, Sandmine machinery Co., ltd released a new product, GIGC series impact crusher. This series Impact hammer crusher is a new generation product which adopts Germany technique, analysis the merits and faults of impact crusher and hammer crusher, combines customers' using feedback. It can be widely used in mining, cement, coal,…

-

Have you ever wondered how big rocks turn into small pieces for buildings, roads, and more? That's where jaw crushers come in—they're like super strong machines that crush big rocks into smaller ones. Imagine this: a big mouth that chomps down on a rock, that's what the jaw crusher does. It has two jaws: fixed jaw and movable jaw moves…

-

The stone industry in Egypt is facing the development difficulties. Firstly, the range of bank financing is small, it only account 5% during the existing stone company. Secondly, the workers lack of the technical training. Thirdly, it required national certification when the stone products export. Wherefore, the Egypt community called on…

SUBMIT YOUR DETAILS

Please provide your information in the form.