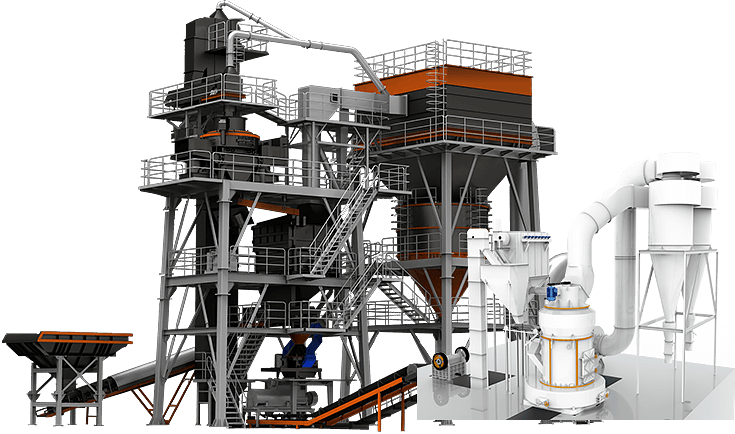

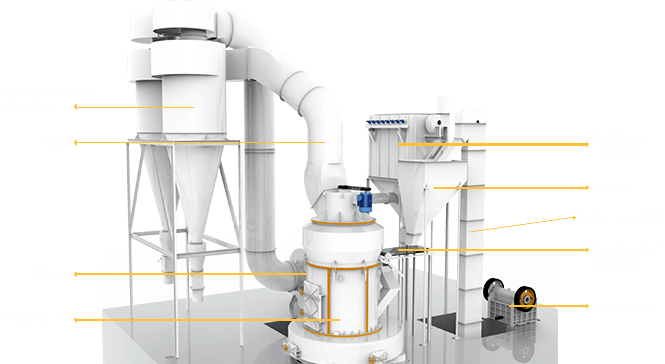

- For raw material with water content higher than 5%, a special water removal system is added on the basis of the standard configuration.

- For raw material with clay content higher than 5%, a special slush removal system is added on the basis of the standard configuration.

- For raw material with water and clay content both higher than 5%, a special water and slush removal systems are added on the basis of the standard configuration.

- For raw material with fine content higher than 5%, a special fine particle classification system is added on the basis of the standard configuration.

- For raw material feeding size bigger than 63mm, a crushing and screening solution will be offered to the customer.